Background on Quest Protective Apparel and Specifically Quantumwear® Suits

From 2000-2006, Quest Safety Products was supplying the Fernald Closure Project, a former uranium processing facility outside Cincinnati, OH with various branded coveralls for mixed asbestos and radiological waste handling. During this period, and through subsequent trials at a number of weapons complex sites nationwide that customers asked Quest to design a coverall suit to truly fit their needs. Through focus groups of industry experts including health physicists, industrial hygienists, safety professional and asbestos workers nationwide, the Quantumwear patented design evolved.

Why These Suits are Significant within the Nuclear Industry

People wearing Quest’s Quantumwear suits are working with some of the most hazardous, dangerous contaminates in the world. A personal contamination event can cost a company anywhere from $5,000 to $40,000 per incident. Click here for an introductory video on Quantumwear suits.

Quantumwear suits provide

- Safety and risk mitigation

- Larger sizing and increased mobility

- Superior protection, comfort, and durability

- Cost effective solutions

Since 2009, our Quantumwear suits have been used by multiple prime contractors at the following Department of Energy sites:

To date, not a single incident of personal contamination has been reported for users wearing Quantumwear or other suits in the Quest Protective Apparel line. This is due to the patented design, fabric, and material construction of our suits.

- Hanford

- Savannah River Site

- Paducah

- Portsmouth

- Oak Ridge

- Los Alamos

- Nevada National Security Site

- Argonne National Labs

Unique Features of Quantumwear and Quantumwear C Suits

Quantumwear and Quantumwear C suits offer the following unique features:

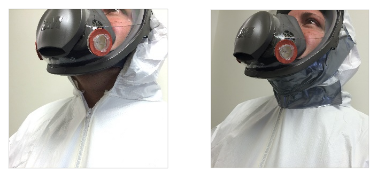

The Patented Quantumwear Neck Closure System: The Neck Closure System is

engineered for an adjustable fit around the head and secure protection around a respirator or

full face mask. With competitor suits, many people use duct tape around the face masks to

insure there is no personal contamination.

Competitor suits, notice the gag that opens if user lifts head

This gap requires many users to duct tape their suits closed to eliminatecontamination. This “fix” can be uncomfortable.

Quantumwear suit: notice the snug fit around the respirator. There is no gap or need for additional duct tape. Our patented Neck Closure System ensures no gaps, continuous protection and comfort for the user.

Donning / Doffing Tabs and Sequencing Procedures: The tab covering the neck and upper check of the Quantumwear and Quantumwear C suits and and donning/doffing sequencing allows the wearer to remove the suit without the risk of contaminating the inside of the suit or themselves. Self-contamination has always been a problem in hazardous industries. Notice that in the images below the hand never touches the wearer or interior clothing.

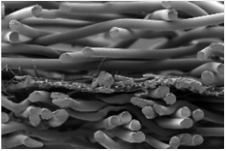

Special Breathable Fabric: That doesn’t require an additional protective layer when working

in hazardous environments. It is light-weight enough to prevent heat stress but impenetrable against

- Micron-sized particles

- Radiological contaminates

- Asbestos, mold, and lead dust

- Environmental hazards

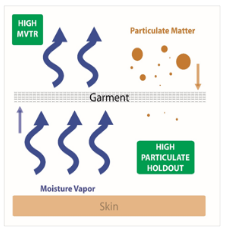

The other secret of Quantumwear is the special fabric we use to keep ultra-fine particles out, as well as hydrophobicly guarding against splash, all while being extremely breathable to ensure heat stress mitigation. We accomplished this with a multi-layered textile, and submitted it to demanding medical testing for particle hold-out, and simulated organic fluid splash penetration tests.

Reinforced Areas: seams, elbows, knees, wrists, and ankles

Elbow and knee areas take the brunt of abuse when users work hard so we have doubled up the fabric in those areas to avoid tears and contamination.

Bound seams join two pieces of material with an overlay of similar material and is chain stitched through all of the layers for a clean finished edge. This provides increased holdouts of liquids and dry particulate.

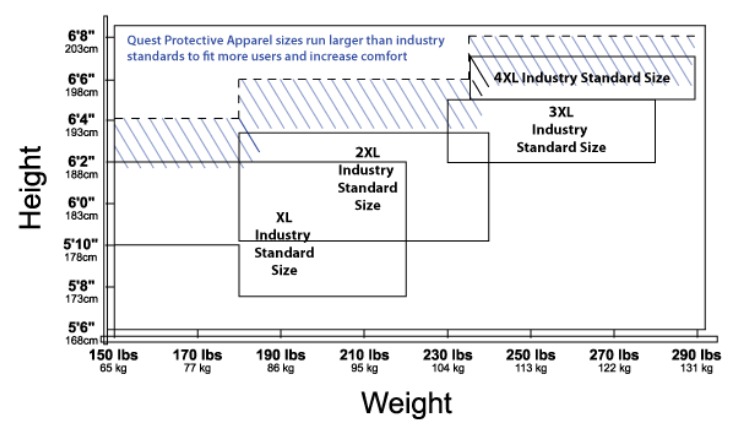

Larger sizing: to prevent tearing, bleed-through and breakouts as users bend, stretch, and work. Larger sizing also allows employers to stock less SKUs of PPE.

Quantumwear Styles and Sizing

Quantumwear comes in two versions: Attached Hood and Boot (H&B) sizes L-8X , and No Hood / No Boot (NHNB) sizes XL-6XL. Both product come 25 suits per case.

Download the product spec sheet here. View the videos below, to see how much better Quantumwear® performs against two brands commonly used in commercial nuclear power, and Department of Energy remediation sites.

Quantumwear C

Quantumwear® C was developed to give workers a more comfortable and functional alternative while working in the following environments:

- Nuclear D/D

- Abatement

- Construction

- Manufacturing

- Cleaning

- Remediation

- Demolition

Quantumwear C Styles and Sizing

Q-Gard Quantumwear® C

Hood & Boot - Yellow,

Taped Seams

Download the product spec sheet here.

Videos

View the following videos to learn more about the Quantumwear suits and how they compare to the competition.

This video covers all the essentials of the Quantumwear suit line. Who was involved in designing the suits, who currently uses the suits, what will this suit do for your workers, where are these suits used.

This video highlights the patented features that make this line of suits unique.

Partical Filtration Tests

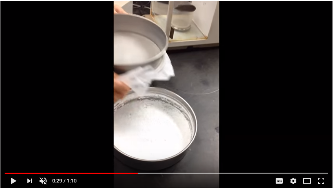

Fabric filtration tests are ran to simulate bacterial / viral filtration efficiency for disposable protective suits/ fabrics, among other contaminants.

The subject fabric is placed between two stacked pans. 25 grams of talc powder is placed in the pan which also has a screen sifter to ensure no talc falls through before the test begins. The pans are placed in the shaker test machine and clamped down. The machine is run for 30 minutes. The test results show how much of the talc filtered through the fabric while the were on the machine.

The talc used in the test was 18% below 2 microns, with the median at 4.5 microns (pretty), and the rest around 10-17 microns. The talc consisted of 31% MgO, 61% SiO2 (residual is FeO and Al2O3).

The test was conducted in the certified textile lab of the manufacturer Quest uses to manufacturer their Quantumwear suits.

Test Subject: Fabric from Quest Quantumwear Suits.

Test Result: Success

The talc did not penetrate the Quantumwear fabric. Quantumwear outperforms almost all other textiles in filtration while still permitting airflow and comfort.

Test Subject: Two layers of a standard polypropolene spun-bound 1.25 oz fabric used on ecomony protective garments.

Test Result: Failure

Almost all of the talc penetrated this fabric. There is only a film of talc left on the fabric’s surface.

Test Subject: Fabric from Lynx Supply's TUFFCAT protective suits.

Test Result: Failure

This video shows that the talc powder did penetrate the TUFFCAT fabric and exactly how much.

Test Subject: Fabric from OREX DELUXE protective suits.

Test Result: Failure

This video shows that the talc powder did penetrate the OREX DELUXE fabric and exactly how much.

Water Resistance: Impact Penetration Tests (AATCC 42)

The following videos show standard Water Resistance: Impact Penetration Tests (AATCC 42) conducted on Quantumwear Suits and four competitive disposable protective suits on the market to see if each fabric allows water to penetrate it.

The test measures the amount of liquid a fabric allows to pass through it when challegend with 500 ml of distilled water out of a shower nozzle 24" above the fabric. In normal tests of this type there is no color added to the water and the blotter paper placed under the fabric is weighed before and after the test to determine the amount of liquid penetration, reported in grams. For this video red food coloring was added to the water so the results could be easily viewed. The same procedures were used for each test.

The tests were conducted in the certified textile lab of the manufacturer Quest uses to manufacturer their Quantumwear suits.

Test Subject: Fabric used with Quest Quantumwear Suits. We sell this suit as splash RESISTANT suit made from splash resitant yet breathable fabric and should not be used as a splash proof or liquid proof garment.

Test Result: Success

The water did not penetrate the Quantumwear fabric.

Test Subject: A 1.25 oz fabric used on ecomony protective garments.

Test Result: Failure

The blotter paper was completely saturated.

Test Subject: Fabric from Lynx Supply's TUFFCAT protective suits.

Test Result: Failure

This video shows the water penetrating the TUFFCAT fabric.

Test Subject: Fabric from OREX DELUXE protective suits. Orex categorizes these suits as splash-resistant.

Test Result: Failure

This video shows the water penetrating the OREX DELUXE fabric.

Test Subject: Fabric from OREX Ultra protective suits. Orex categorizes these suits as total barrier protection.

Test Result: Failure

This video shows that this fabric performed much better than the DELUXE fabric but water was still able to penetrate the fabric in a few places.